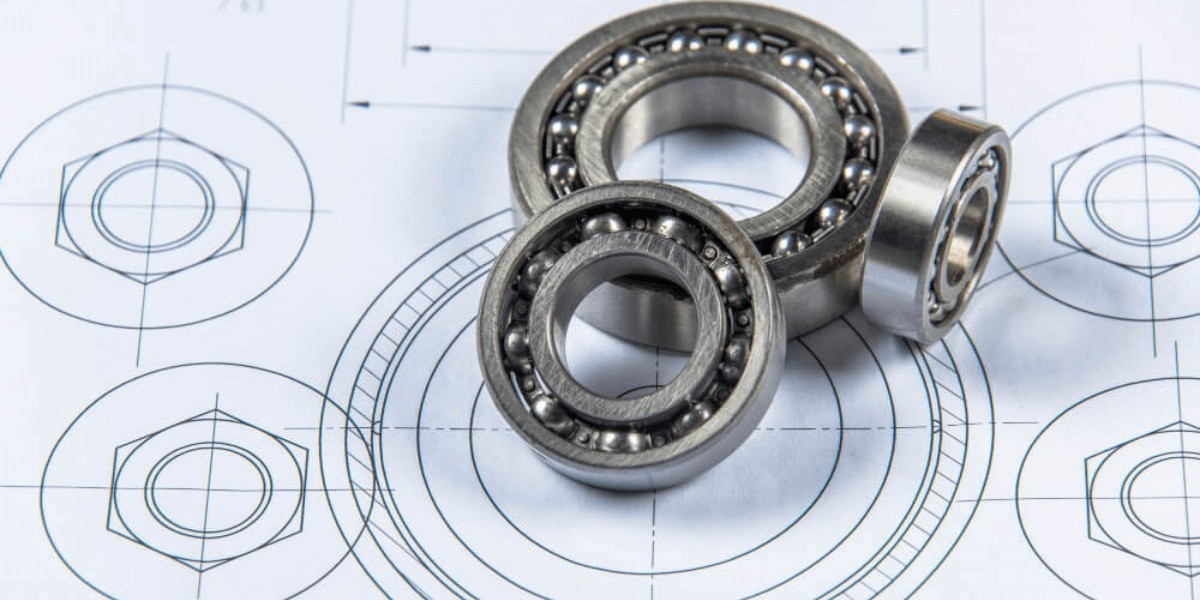

Not every machine is built the same — so why settle for one-size-fits-all components? In industries where performance, precision, and durability matter most, relying on standard bearings often leads to misalignment, premature wear, and operational inefficiency.

That’s where a customized bearing solution becomes essential. By designing bearings that perfectly match your equipment’s specific requirements, manufacturers can drastically reduce downtime, extend service life, and improve overall machine performance.

Whether you operate in automation, aerospace, medical, or heavy industrial sectors, custom-engineered bearings deliver the tailored performance your machinery demands — without compromise.

The Problem: Why Standard Bearings Can Limit Machine Performance

Many engineers and operators face repeated challenges with off-the-shelf bearings that don’t perfectly fit or perform as needed. Common issues include:

Poor Fit or Tolerance Mismatch: Causes vibration, noise, or shaft damage.

Reduced Bearing Life: Incompatible designs accelerate fatigue and wear.

Overheating and Friction: Due to misalignment or incorrect load distribution.

Frequent Maintenance Interruptions: Causing unexpected downtime and higher operational costs.

These challenges often result from using generic bearings in specialized applications — a costly mistake that can affect production quality and machine longevity.

The solution? A customized bearing engineered precisely for your load capacity, temperature range, environment, and speed requirements.

What Makes Customized Bearings a Smart Investment

1. Tailored Design for Perfect Fit

Customized bearings are designed from the ground up based on shaft size, load direction, rotational speed, and operating environment. This ensures flawless integration with your machine’s mechanical system.

2. Superior Material Selection

Depending on your needs, materials like stainless steel, ceramic, or hybrid composites can be used to improve strength, corrosion resistance, and thermal performance.

3. Enhanced Performance and Efficiency

Custom designs allow for optimized raceway geometry, improved sealing systems, and precision lubrication — resulting in smoother rotation, lower friction, and longer bearing life.

4. Adaptable for Extreme Environments

Whether you need bearings for high-temperature furnaces, underwater equipment, or cleanroom conditions, customization ensures durability and reliability under any condition.

5. Reduced Downtime and Maintenance Costs

Because customized bearings fit perfectly and perform optimally, they require less maintenance, reducing downtime and extending service intervals — leading to a measurable ROI.

Applications That Benefit from Customized Bearings

Customized bearings are essential in applications where standard solutions cannot meet unique performance demands. Some key sectors include:

Robotics and Automation: For precise movement, minimal vibration, and compact design.

Aerospace and Defense: Bearings designed to withstand extreme pressure, temperature, and rotational speeds.

Medical Equipment: High-precision, low-noise bearings for surgical and diagnostic devices.

Renewable Energy Systems: Bearings built for long-term stability in turbines and wind generators.

Heavy Machinery and Mining: Reinforced bearings capable of handling massive loads and harsh environments.

Each of these industries demands reliability, and customized bearings ensure every operational variable is accounted for.

Yuwei Bearing: Engineering Customized Solutions That Perform

At Yuwei Bearing, customization isn’t just an option — it’s a commitment to delivering engineering excellence. With decades of experience in bearing manufacturing, Yuwei combines innovation, precision, and technical expertise to create tailor-made solutions for diverse industrial needs.

1. Collaborative Design Process

Yuwei works directly with clients to analyze performance goals, machine specifications, and environmental factors. The result? Bearings optimized for durability, precision, and efficiency.

2. Advanced Manufacturing and Quality Control

Using CNC machining, robotic assembly, and strict ISO-certified testing, Yuwei ensures each bearing meets exact client specifications — from geometry and surface finish to internal clearance and noise level.

3. Wide Range of Customization Options

Bearing Type (ball, roller, thrust, or hybrid)

Material Composition

Sealing and Shielding Options

Lubrication System (grease, oil, or solid film)

Dimensional Adjustments (tolerance and clearance control)

4. Performance You Can Trust

Every Yuwei customized bearing undergoes vibration analysis, friction testing, and load simulation to ensure reliability in real-world applications.

How Customized Bearings Add Value to Your Operations

The benefits of adopting customized bearings extend far beyond technical compatibility:

Increased Productivity: Consistent performance ensures uninterrupted operations.

Reduced Energy Loss: Lower friction means better efficiency.

Enhanced Machine Precision: Perfectly matched tolerances reduce vibration and error rates.

Lower Long-Term Costs: Fewer replacements, less maintenance, and reduced downtime.

Sustainable Operations: Optimized bearing life means less waste and better energy utilization.

These advantages make customized bearings not just a technical enhancement — but a strategic investment.

Conclusion

If you’re facing recurring mechanical issues due to bearing mismatch or premature failure, it’s time to switch to a reliable solution. Partner with Yuwei Bearing — the industry expert in customized bearings engineered for precision, performance, and durability.

? From design consultation to final delivery, Yuwei ensures every bearing is built to exceed your expectations. Choose Yuwei for superior customization, advanced materials, and long-term machine efficiency.