The polyisoprene market share attained a volume of 18.56 Million Tons as of 2024 and is anticipated to grow at a CAGR of 5.50% during the forecast period of 2025 to 2034. The polyisoprene market is dominated by the growing demand for hypoallergenic and biocompatible materials in the medical industry. Synthetic polyisoprene is used as a substitute for natural rubber in medical devices like gloves and catheters due to its better elasticity and lower risk of allergic reactions. This trend is also driven by the growing number of surgeries and increased hygiene standards. The market is thus expected to reach a volume of nearly 31.70 Million Tons by 2034.

Introduction to Polyisoprene

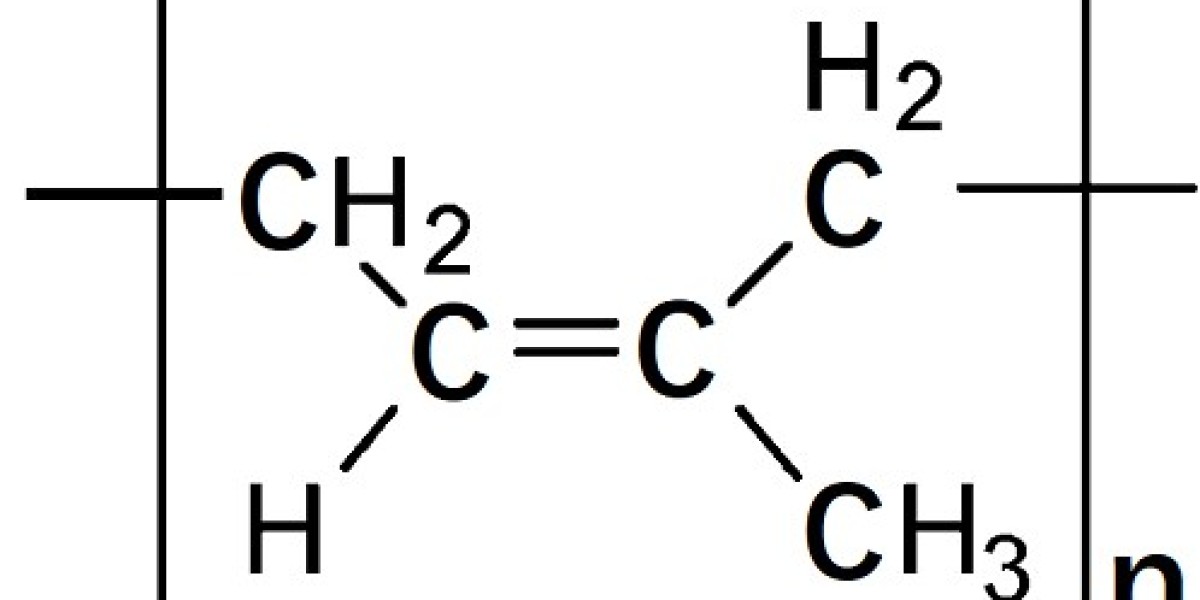

Polyisoprene, a polymer of isoprene, is one of the most versatile elastomers widely used across industries such as healthcare, automotive, and consumer goods. It exists in two forms: natural polyisoprene, derived from rubber trees, and synthetic polyisoprene, produced through polymerization processes. While natural rubber has been a staple in industrial applications for decades, synthetic polyisoprene has gained prominence for its consistent quality, hypoallergenic properties, and superior physical attributes, making it particularly valuable in medical and hygiene products.

With growing concerns over latex allergies and the need for safer alternatives in healthcare environments, polyisoprene has emerged as a critical solution. As global healthcare systems continue to prioritize patient safety and quality, the material’s applications are expanding rapidly.

Key Growth Drivers of the Polyisoprene Market

1. Rising Demand in the Medical Sector

The medical industry is one of the largest consumers of synthetic polyisoprene. Its biocompatibility, elasticity, and non-allergenic properties make it ideal for surgical gloves, catheters, condoms, and other disposable medical products. With the increasing number of surgeries worldwide, coupled with stricter hygiene standards in hospitals and clinics, demand for polyisoprene-based products is expected to rise significantly.

2. Growing Concerns Over Latex Allergies

Latex, though widely used, poses the risk of allergic reactions in patients and healthcare professionals. This has led to a global shift toward synthetic substitutes like polyisoprene. The material mimics the mechanical properties of natural rubber without the associated risks, positioning it as a safer and more reliable alternative.

3. Expansion in Automotive and Industrial Applications

Beyond healthcare, polyisoprene is also widely used in the automotive sector for manufacturing tires, vibration control components, and seals. Its resilience and ability to withstand stress make it suitable for heavy-duty industrial applications. As global automotive demand increases, especially in developing economies, polyisoprene is expected to benefit.

4. Hygiene Awareness and Preventive Healthcare Trends

The COVID-19 pandemic heightened awareness about hygiene and preventive healthcare worldwide. Even in the post-pandemic era, the demand for disposable gloves, condoms, and other protective products has remained strong. Polyisoprene, being a premium material for these applications, continues to see sustained growth.

5. Technological Advancements in Polymerization

Innovations in polymerization technologies have made it possible to produce synthetic polyisoprene with tailored properties. This ensures better performance, consistency, and cost-effectiveness, further driving its adoption across sectors.

Market Challenges

While the future looks promising, the polyisoprene market faces certain challenges:

High Production Costs: Synthetic polyisoprene is costlier to produce than natural rubber, which can limit its affordability in price-sensitive markets.

Competition from Substitutes: Other synthetic rubbers and elastomers compete with polyisoprene in industrial applications, potentially restraining its demand.

Environmental Concerns: As a petroleum-derived product, synthetic polyisoprene raises concerns about sustainability and environmental impact. The development of bio-based alternatives may become a crucial factor for long-term growth.

Regional Insights

North America: The United States is a key consumer of synthetic polyisoprene, particularly in the healthcare sector. Strong healthcare infrastructure and demand for advanced medical devices drive the market.

Europe: European countries are adopting synthetic polyisoprene due to strict regulations against allergenic materials. The region also shows strong demand in automotive applications.

Asia-Pacific: The largest and fastest-growing market, driven by rapid industrialization, expanding healthcare facilities, and rising automotive production. Countries like China and India are witnessing increased demand for both natural and synthetic polyisoprene.

Latin America and Middle East & Africa: These regions are emerging markets with growing healthcare needs and expanding automotive industries, offering untapped potential for polyisoprene producers.

Future Outlook

The next decade is expected to bring robust growth for the polyisoprene market. By 2034, the market is projected to reach 31.70 Million Tons, reflecting the rising importance of this material across industries. With the medical sector leading the way, polyisoprene is set to become a cornerstone in ensuring patient safety and meeting global healthcare demands.

Moreover, sustainability will play an increasingly significant role in shaping the market. Manufacturers are investing in research to develop eco-friendly production methods and explore bio-based polyisoprene alternatives. As consumer awareness of environmental issues grows, companies that adopt sustainable practices are likely to gain a competitive edge.