I. Introduction

Define porous/permeable paving: paving systems that allow water to infiltrate through joints, voids, or porous material into the sub-base.

Why it matters: stormwater management, urban flooding prevention, sustainability, and groundwater recharge.

Growing demand: climate change, stricter environmental regulations, and eco-conscious landscaping.

II. Types of Permeable Paving Systems

Permeable Interlocking Concrete Pavers (PICP)

Concrete pavers with small gaps filled with aggregate to allow infiltration.

Porous Asphalt & Concrete

Special mix design with higher void content to allow water passage.

Natural Stone with Permeable Joints

Flagstone, cobblestone, or cut stone installed with permeable jointing material (sand, gravel, resin-bound aggregates).

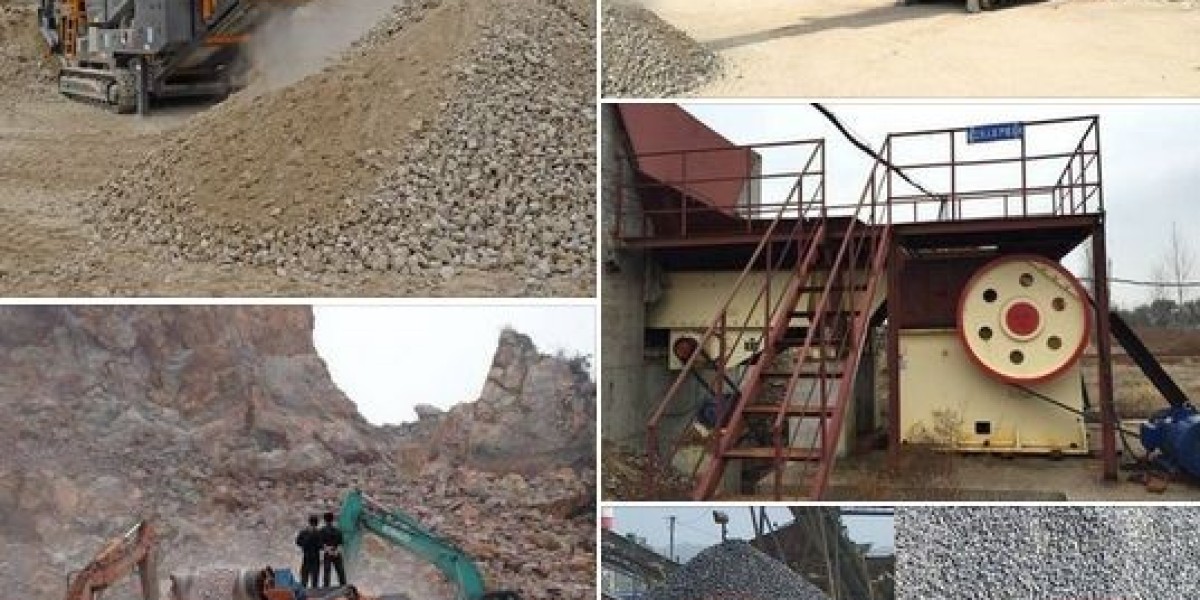

Gravel & Stabilized Stone Systems

Loose gravel with stabilizing grids or honeycomb structures for traffic-bearing capacity.

Green / Hybrid Solutions

Grass pavers, turf grids, or mixed stone-and-vegetation systems for parking or light traffic.

III. Key Installation Components

Surface Layer: stone, pavers, or porous concrete.

Joint Fillers: gravel, sand, resin-bound aggregates.

Base/Sub-Base Layers: graded aggregate for water storage and filtration.

Geotextile Layers: to separate soil and aggregate, preventing clogging.

Drainage Outlets: optional underdrains for areas with low soil infiltration.

IV. Benefits of Porous/Drainage-Friendly Stone Installations

Stormwater management: reduces surface runoff, prevents flooding.

Groundwater recharge: allows water to seep into soil aquifers.

Pollution control: filters sediments, oils, and debris before water enters groundwater.

Heat island reduction: cooler surfaces than asphalt.

Durability & aesthetics: natural stone offers both performance and beauty.

Regulatory compliance: helps meet green building codes and water management laws.

V. Challenges & Considerations

Clogging risk: requires maintenance (vacuuming, jet washing, debris removal).

Cost: higher upfront compared to conventional paving.

Load-bearing limits: not always suitable for heavy trucks unless properly engineered.

Climate limitations: freeze-thaw cycles, soil type, and rainfall patterns affect design.

Design expertise: requires correct base grading and engineering to perform well.

VI. Best Practices for Installation

Site assessment: soil infiltration rate, drainage patterns, load requirements.

Proper excavation and sub-base preparation.

Use high-quality permeable aggregates for filling.

Ensure slope control (usually 1–5% for effective drainage).

Design for overflow (emergency drainage for extreme rainfall).

Maintenance plan: regular inspections and cleaning.

VII. Future Trends

Integration with smart stormwater systems (IoT sensors to monitor water flow).

Hybrid eco-paving: stone + vegetation mixes.

Use of recycled materials (crushed concrete, recycled glass) in permeable systems.

More government incentives and mandates for sustainable drainage solutions.

Urban retrofitting: replacing conventional hardscapes with permeable paving.

VIII. Implications

For homeowners/landscapers: sustainable, attractive, low-impact paving choice.

For municipalities: tool to manage urban flooding and meet stormwater regulations.

For contractors: new opportunities in green infrastructure projects.

For developers: improves project sustainability ratings (LEED, BREEAM, etc.).